Specialized blog for the industry

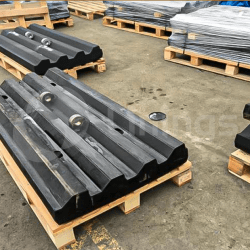

Its known that the caps of a mill are not decisive for grinding, as shell liners can be to a certain extent. However, it is important that the cap liners comply as far as possible with a stable duration time, which may be equal to the useful life of the shell liners or half of their useful life. In this way, plant stoppage interruptions due to cover replacement are avoided. In a 12x16 all-steel lined ball mill, the customer had problems with their caps that he had to make continual changes to, as the life of the feed cap was around 3 months and the discharge cap around 3 months. 6 months. Linings developed its composite cover model for this client, which has been able to deal with the problem of duration: supply cover between 5 and 6 months, discharge cover around 11 months. This has meant a 90% increase in the duration of their caps, thus having fewer stops during their campaign. In addition to this, as the liners are lighter than pure steel designs, a reduction in man-hours per installation and lower energy consumption is achieved.

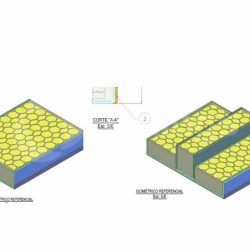

Liners are not only part of the mill casing protection, but also play an important role in grinding efficiency. Cases have been studied where it is developed through simulations and experimental verification that composite mill Liners (which are a part of rubber and steel materials) are considered a new trending technology in the mining industry. When a mill migrates from Steel Liners to composite mill Liners, it normally reduces its weight between 35% to 55%, generating less power consumption (Kw) in the mill and reducing its energy consumption (Mwh) by around 4% to 7%. . In the case of Peruvian mining, the value of energy is around 0.055 USD/Kwh; while in Chile it has a value around 0.12USD/Kwh. composite mill Liners help reduce energy consumption in grinding and it is up to each country to consider how they manage their energy cost factor.

We provide metallurgical consulting in research, development and optimization in mineral processing of concentrator plants and laboratory services in the areas of comminution and flotation. We always seek the satisfaction of our clients based on the high specialization and experience of our top-level team within the metallurgical industry in Mexico, who allow us to deliver reliable, high-quality studies and projects.