Composite mill Liners in grinding and their impact on energy cost

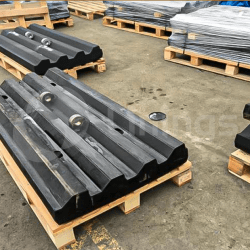

Liners are not only part of the mill casing protection, but also play an important role in grinding efficiency. Cases have been studied where it is developed through simulations and experimental verification that composite mill Liners (which are a part of rubber and steel materials) are considered a new trending technology in the mining industry.

When a mill migrates from Steel Liners to composite mill Liners, it normally reduces its weight between 35% to 55%, generating less power consumption (Kw) in the mill and reducing its energy consumption (Mwh) by around 4% to 7%. .

In the case of Peruvian mining, the value of energy is around 0.055 USD/Kwh; while in Chile it has a value around 0.12USD/Kwh. composite mill Liners help reduce energy consumption in grinding and it is up to each country to consider how they manage their energy cost factor.

Lower weight, less power consumption in grinding.

Blog