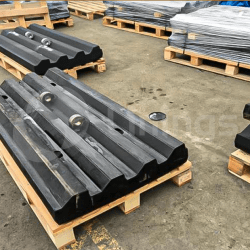

[Success story] Liners type SB60 – Polywear RC

Place of installation: Chute of fines from the Trommel of the SAG Mill.

The client previously used rubber liners that lasted approximately 4 months; now with the new proposed design of Linings, it has been possible to increase the lifespan to approximately 11 months, which has reduced plant stoppages to change this type of product.

Our innovative design proposal consisted of sectioning it into three pieces with ceramic rubber, incorporating a lifter bar in the most critical area. This recreates a dead bedding zone of material which helps extend the life of the Liners; In addition, it includes 500 HB laminated steel in strategic areas to prevent tearing or chipping of ceramics as a result of the great impact of the ore rocks.

For this project, 38mm high ceramic pads were used. The configuration that the ceramic inserts have have been created and are in the process of being patented by Linings . These are overlapped in the direction of flow, thus avoiding wear lines that shorten the life of the liners. In addition, this design prevents tearing of the inserts by keeping them in position until the end of their useful life.

Blog