Our product lines

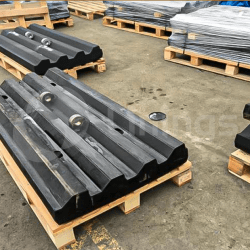

Linings for Ball and SAG Mills

We provide solutions to prevent wear due to abrasion, impact, fatigue, or fracture of mill parts in the grinding process. Our linings, which can be made of rubber or composite, rubber with laminated steel or rubber with high chrome casting, are manufactured with raw material from certified suppliers, which we have approved over the years, obtaining the desired values together with them. in order to present a superior quality product. By developing these high-quality raw materials, we will obtain the following benefits:

REDUCES COSTS

- Energy savings due to reduction in weight of rubber or composite mill linings (savings of approximately 40% decrease in weight).

- Savings in maintenance times. Lighter parts make the lining installation faster, using less man-hours to install the linings.

IMPROVES PRODUCTIVITY

- We propose designs that improve productivity in your operation.

- Our designs are validated by simulations and our metallurgical specialists, who ensure compliance of the proposed improvements with the design changes.

OCCUPATIONAL HEALTH

- Reduction of decibels produced by the mill, compared to a 100% cast format liner.

- Lighter parts that reduce the risk of accidents inside the mills.

Ceramic liners

Our ceramic products have 95% alumina (superior quality), which are inserted in the rubber that traps them for a better performance as a whole. We work on these ceramic liners tailored to our clients with personalized applications for each operation. The areas that most demand our ceramic products are Primary Crushing, Overland Belts, Apron Feeders, Concentrator Plant, Fines Plant, Tailings Area, etc. For this type of product, we handle various ceramic tablet formats, which are defined depending on the workload applied to this type of ceramic Liners.

Other rubber products

We develop rubber products depending on the customer's needs, maintaining quality throughout the manufacturing process.

Our experience, technical team and technology allow us to develop projects according to the needs of each client. We manufacture any format that the client may require and using the type of rubber that best suits the type of operation in which it will be used: 40 SH, 60 SH, etc.

Blog