Myths about composite mill Liners

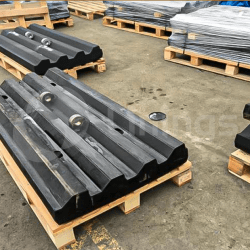

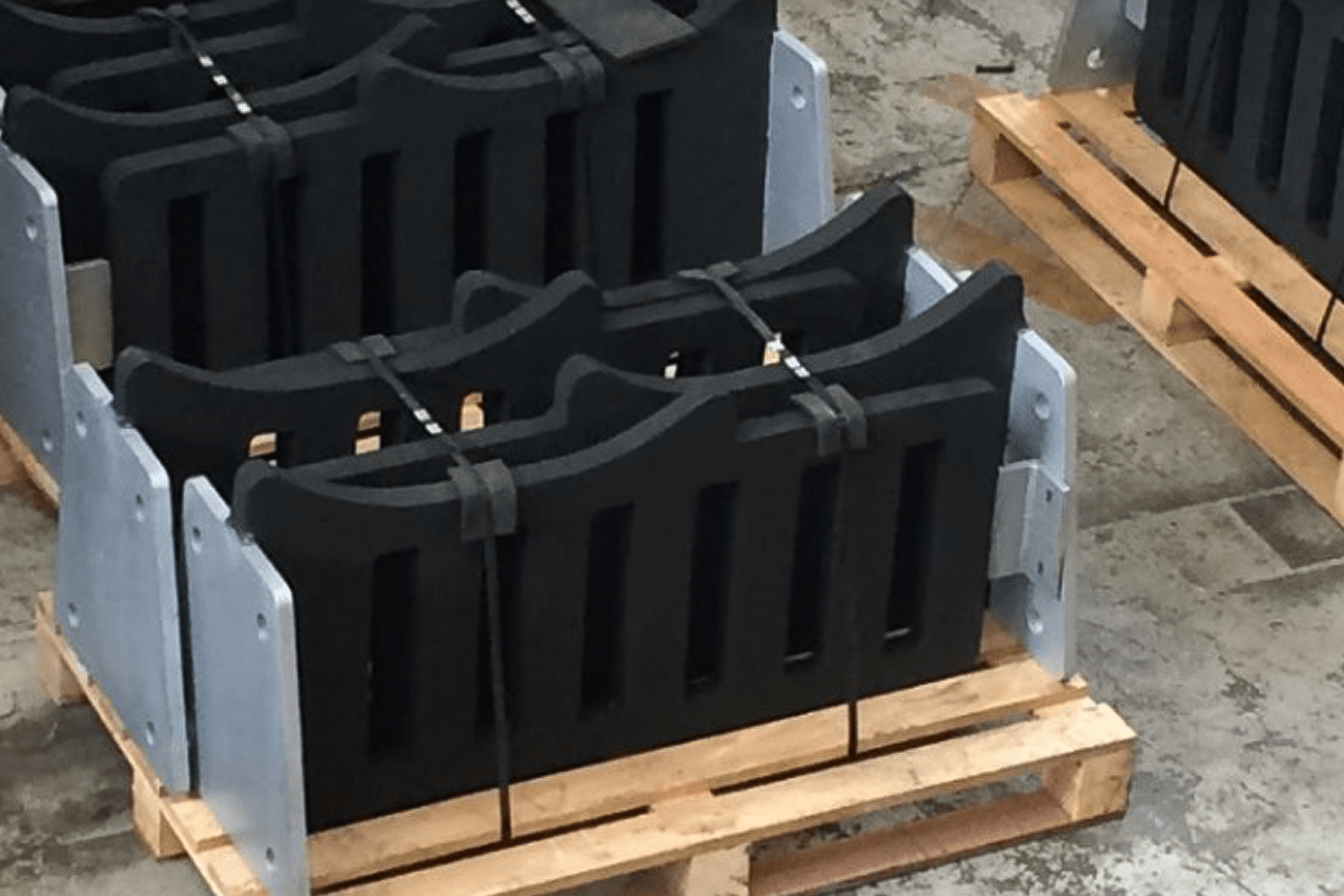

Referring to the linings for ball mills and SAG mills, there are still doubts about the use of materials known as composite. The most conventional use for these applications is with steel linings or liners, which is why it is often mistakenly believed that the change from steel liners to a composite format will be detrimental to the mill.

Here are 3 myths that come to light when thinking about composite mill liners:

- “The rubber (rubber or rubber) contained in these liners do not grind like steel liners”

It is the grinding media that is responsible for grinding the ore, not the lining. In the operation of the mills, the one who carries out the correct movement of the grinding load is the lining. In this way, as there is contact between balls, mineral and lining, the latter will suffer the consequences of wear and, if it quickly loses its angle of attack (whether in rubber or steel material), grinding will be impaired. Our composite mill liners are designed in such a way that the angle of attack lasts as long as possible.

- “Hybrid coatings last less than steel coatings”

Some users have perceived their composite mill linings to be less durable compared to steel ones, however this is not simply limited to the composite mill lining concept as there are many factors that influence durability which can be broken down into operational and operational factors and design factors.

Operating factors are those related to the change in operating conditions and the new type of ore treated.

The design factors are related to both the liner metrics and the materials used, which often due to design flaws, do not meet the requirements for a given operation.

Therefore, as a general rule, a composite design lasts longer than a steel design. A well-done composite design, operating under the same conditions, will always outlast steel liners.

- “Composite liners are very expensive to operate”

The benefits of changing mill linings to composite mill linings far outweigh the cost of the lining. Regardless of the magnitude of the operation (large, medium or small), nothing more than the reduction of energy consumption (among other advantages) and knowing how to channel this advantage with respect to steel liners, the production that the plant can reach will pay by far the cost of composite mill liners. We advise our clients so that this advantage materializes.

Blog